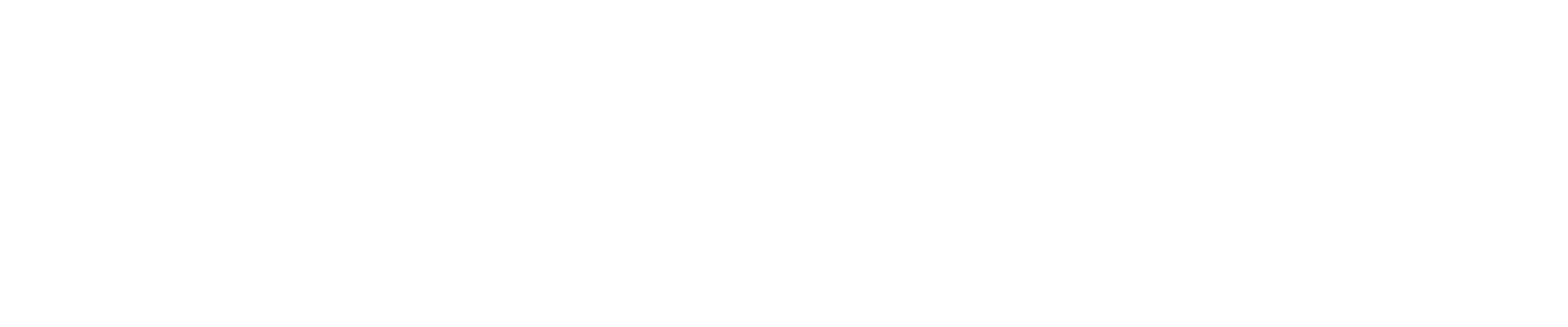

HIGH SPEED PRECISION HOT/WARM FORGING PRESSES VFP-600/4000T

1. The steel plate at the top of the frame is strengthened, greatly improving the rigidity of the frame, reducing deformation, and considering the convenience of installation and maintenance.

2. The deflection design of the workbench is above 1/12000, improving the accuracy of forgings and the lifespan of molds.

3. The frame is thickened through the plate, improving the rigidity of the frame.

4. The rack is annealed to enhance its stability.

5. The rack has undergone finite element analysis and optimized design, resulting in an overall rigidity improvement of about 10%. The total design resistance is nearly 10 times before variables occur.

HIGH SPEED PRECISION HOT/WARM FORGING PRESSES VFP-600/4000T

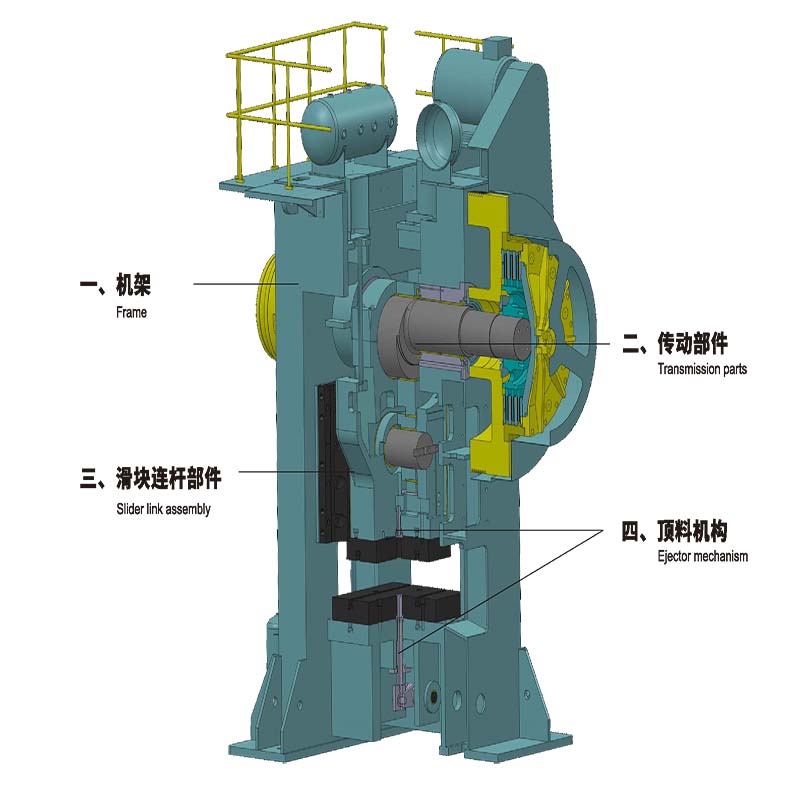

The high-performance alloy steel 42CrMo is adopted, the yield limit is 2.6 times that of 45# steel, and the hardness HB after heat treatment is more than 300. The cranksha ft diameter is increased, which is more than 20% heavier than the domestic MP model, and the stress is increased by more than 35%.

Clutch:

The multi group friction disk structure design is adopted, which has greater friction torque than the general friction block structure design, so that the equipment has greater working capacity, reduces energy consumption, saves energy and reduces emissions, and saves at least 10%more energy than the traditional precision forging machine.

Slider link assembly

Double connecting rod design is adopted to greatly improve the eccentric load capacity. The sliding block adopts box type ca st st ee l structure and elongated octahedral guide rail design, which can maintain high accuracy and bear high eccentric load. The guide plate is made of high wear-resistant material, so that the load capacity of the machine can reach 80-100% of the full load at each station, and the multi work position has strong anti bias load capacity.

The equipment adopts electromechanical integrated control

1. PLC control, electronic cam control panel and Chinese man-machine interface are adopted for equipment control.

2. To achieve accurate control of the equipment, the operation mode: inching, single time, continuous, mold change, stop, five gears.

3. Automatic equipment connection, process parameter programming and setting can be carried out, and corresponding programs can be called when different parts are produced.

4. When the equipment monitoring point sends out protection information, it is directly displayed on the display screen so that maintenance personnel can quickly identify and repair; The man-machine interface has built-in electrical diagram and maintenance schematic diagram, which is convenient for maintenance personnel to quickly identify.

5. Real time accurate display of tonnage.(optional)

6. Remote assistance, cooperate with enterprise remote management, and the real-time data is consistent with the mobile terminal data.(optional)