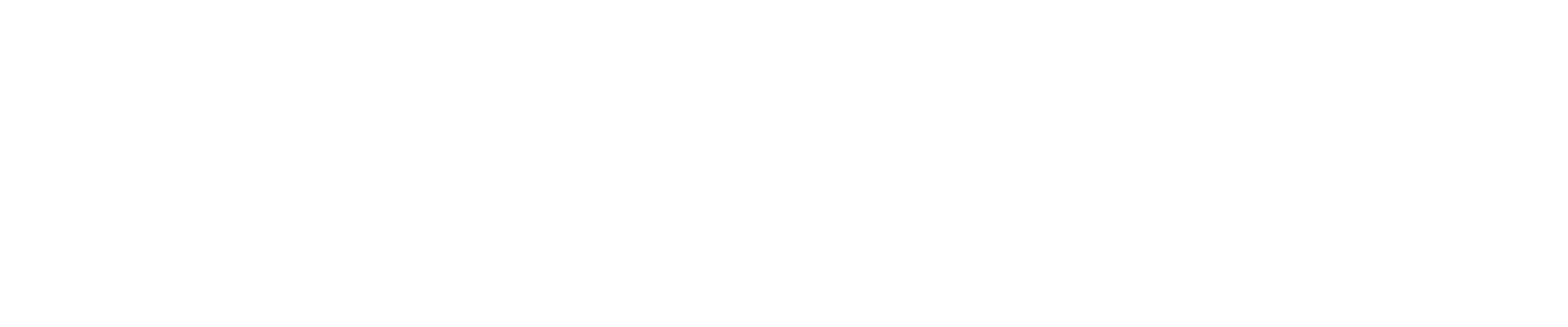

JH31、JY31 SERIES HIGH-PERFORMANCE CLOSED TYPE SINGLE POINT PRESS (CRANKSHAFT TRANSVERSE)

1、The frame adopts finite repeated analysis to optimize the design and make the frame rigid.

2、Double table design is adopted to improve rigidity.

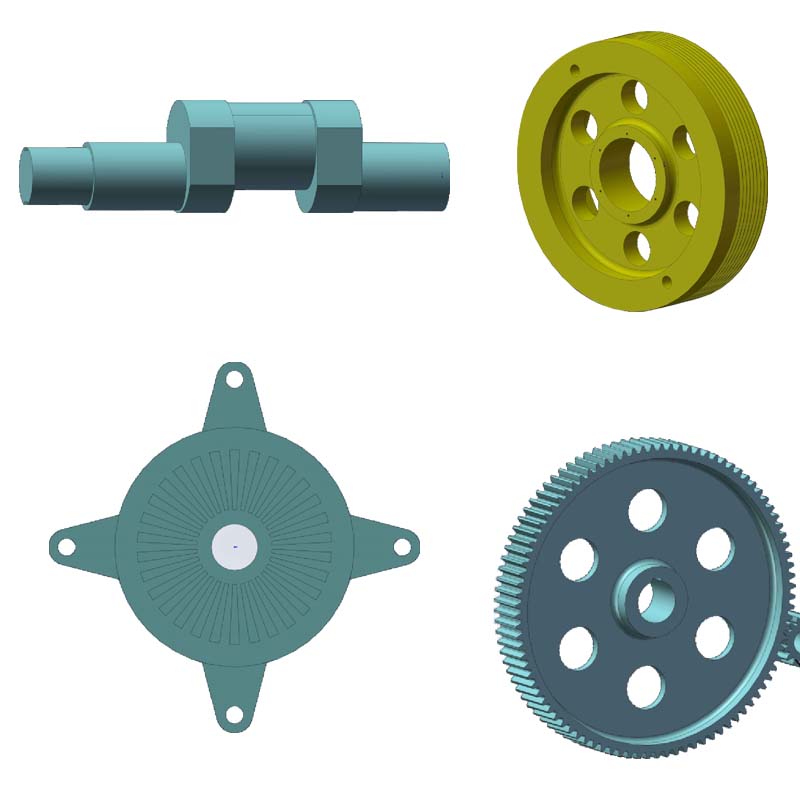

3、The cranksha ft material is changed from the original 45# steel to alloy steel 42CrMo, the yield limit is increased by 2.6 times, and the hardness is above HB300. Improve wear resistance, toughness and service life.

4、The slider material is changed from the original gray iron casting to nodular cast iron, which improves the compression and wear resistance and has high toughness.

1、The slider guide is changed from four sided guide rail to eight sided guide rail, which improves the guide performance and anti deflection ability.

2、The slider is changed from the original manual mold height adjustment to the automatic mold height adjustment, reducing the labor intensity of employees.4. The ball joint material is changed from the original 45#steel forging to the alloy steel42CrMo forging, which improves the wear resistance, toughness and service life.

3、The static balance process is adopted to eliminate the body shake and improve the bear ing life.

4、 The dry pneumatic friction cl utch is adopted, which is convenient for maintenance and improves safety and reliability.

5、The design torque is 1.3t imes of the approved torque, improving the reliability of the equipment.