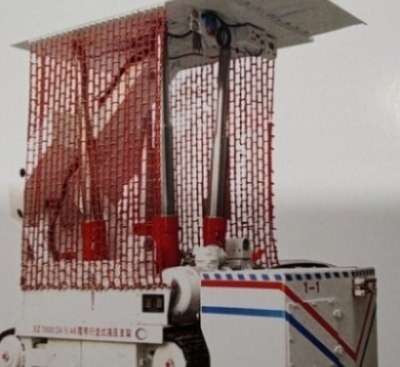

EBZ160T Road Header

“Drill when in doubt, first drill and then tunnel”. EBZ160T cantilever road header is designed for the unknown geological conditions or the existence of dangerous sources (water, gas, etc.) in the mining process of coal mines. lt is a kind of all-in-one digging machine that integrates the functions of tunneling and advanced drilling construction. The drilling machine carried by this machine can effectively complete the advanced drilling construction within a certain range of the full mechanized mining face.

EBZ160T cantilever road header is designed for the unknown geological conditions or the existence of dangerous sources (water, gas, etc.) in the mining process of coal mines. lt is a kind of all-in-one digging machine that integrates the functions of tunneling and advanced drilling construction. The drilling machine carried by this machine can effectively complete the advanced drilling construction within a certain range of the full mechanized mining face.

EBZ160T Road Header Technical parameters:

1、Overall dimension(m) 10.9x281x21

2、Positioning tunneling height/width(m) 2.5-4.0/3.8-5.5

3、Unidirectional compressive strength of rock subject to economical cutting(MPa) ≤60

4、Dinting depth (mm) 250

5、Ground clearance (mm) 250

6、Suitable tunnel gradient(°) ±16

7、Ground pressure (MPa) 0.15

8、Overall weight (t) 55(excluding second conveyor and dust removal system)

9、Total rated power (kW) 250 (excluding second conveyor and dust removal system)

10、Supply voltage (V) 1140

11、Max non-removable parts size (m) 3.3x1.5x1.45(front rack) 5.4x0.6x0.26 (sliding rail)

12、Max non-removable parts weight(t) 5.8 (front rack)

| Parameters of EBZ160T road header's drilling rig (750 drilling rig) | ||

| S/N | Item | Technical parameters |

| 1 | Drilling depth (m) | ≥70 |

| 2 | Drill pipe diameter(mm) | φ42 |

| 3 | Drilling hardness | f≤8 |

| 4 | Rated torque (Nm) | 750/280 |

| 5 | Rated speed (r/min) | 105/270 |

| 6 | Drilling method | Wet type |

EBZ160T Road Header Technical features:

1.With the advanced drilling rig integrated into the machine body, this machine improves the roadway adaptability of the all-in-one digging machine;

2.During tunneling, the advanced drilling rig shall return to the rear of the cuttingsection. During the construction of the advanced drilling,the advanced drilling rig shall move to the front of the cutting section to realize the continuous operation of tunneling and driling;

3. The accurate and stable drilling rig is equipped with a mobile positioning device to realize the complete mechanization of the advanced drilling construction, reduce the labor intensity of workers, and improve the safety and effciency of the advanced drilling construction;

4. Advanced drilling only needs two people during the whole construction operation, which effectively reduces the manniing;

5. The tunneling and advanced drilling construction of the roadways has hydraulic and electrical interlocking functions, with high overall operation safety.