High-effciency And Energy-saving Stepping Self-moving Equipment Train

Technical features

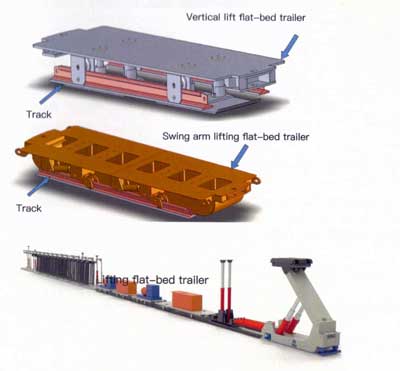

1. Instead of the traditional winch wire rope traction, the mine electric control

hydraulic mobile train set is highly integrated with the functions of train self-movement, travel deviation adjustment, pipe and cable follow-up, and lane fallingprevention etc., so as to realize the step forward movement of the entire mineelectric control hydraulic mobile train set driven by the anchor traction device.

2.Electronically controlled hydraulic mobile train set for mining has its own trackinstead of manual track laying; Shorten the moving time of the mine-specificelectric-controlled hydraulic moving train set, and reduce the cost of thematerials such as track sleeper, etc.; Avoid frequent track-laying operation whenoperators use rail transportation to ensure the safety of operators.

3.The pipe and cable telescopic bearing system has completely replaced the roofmonorail crane cable device. It does not need to manually drag the cable and laythe track. The cable length has also greatly reduced, from more than 100 metersin the past to only more than 30 meters, which greatly reduces the labor intensityof workers and realizes the automatic expansion and contraction of complete setof fully mechanized mining face and water pipes.

4. There are various options of manual control, electro-hydraulic control and remote

control for the mine-used electro-hydraulic mobile train set.

Cases and effects of applications

1.The number of supporting operators has been reduced from 15 in the past to 4 at present, a decrease of 73%

2.The economic cost is saved by about 1.3 million yuan, and the labor cost can be saved by 800,000 yuan every year.

3.The duct cable telescopic device completely replaces the traditional monorail crane form, dragging the cable manually is not needed, and the length of the cable is reduced by 75%.

4.The coal mining effciency is increased by more than 10%, and the consumption of consumables such as sleeper is reduced by about 70%.

Technical features

1. Instead of the traditional winch wire rope traction, the mine electric control

hydraulic mobile train set is highly integrated with the functions of train self-movement, travel deviation adjustment, pipe and cable follow-up, and lane fallingprevention etc., so as to realize the step forward movement of the entire mineelectric control hydraulic mobile train set driven by the anchor traction device.

2.Electronically controlled hydraulic mobile train set for mining has its own trackinstead of manual track laying; Shorten the moving time of the mine-specificelectric-controlled hydraulic moving train set, and reduce the cost of thematerials such as track sleeper, etc.; Avoid frequent track-laying operation whenoperators use rail transportation to ensure the safety of operators.

3.The pipe and cable telescopic bearing system has completely replaced the roofmonorail crane cable device. It does not need to manually drag the cable and laythe track. The cable length has also greatly reduced, from more than 100 metersin the past to only more than 30 meters, which greatly reduces the labor intensityof workers and realizes the automatic expansion and contraction of complete setof fully mechanized mining face and water pipes.

4. There are various options of manual control, electro-hydraulic control and remote

control for the mine-used electro-hydraulic mobile train set.

| No. | Name | Parameter | ||

| 1 | Equipment train type | Stepping and self-moving | ||

| 2 | Climbing angle | 0°— 18°(two sets of anchor traction devices) | ||

| 3 | Traction capacity | 140T | ||

| 4 | Moving step distance | 2000mm | ||

| 5 | Length of heavy rail | 6370mm/4060mm | ||

| 6 | Traction jack | Specifications | φ250/φ180 mm,2 pieces/set | |

| Tractive force (P=30 MPa) | 147.1KN | |||

| Traction (P=30 MPa) | 71.2KN | |||

| 7 | Lifting jack | Specifications | φ100/φ70mm | |

| Thrust (P=30 MPa) | 120KN | |||

| Tensile force (P=30 MPa) | 235.5KN | |||

| 8 | Load capacity | 400T | ||

| 9 | Height of flat-bed trailer | ≤0.45m | ||

| 10 | Control mode | Electro-hydraulic control/remote control/automatic control | ||